Unlocking Efficiency: The Transformative Benefits of the Best Film Blown Machine in Modern Packaging

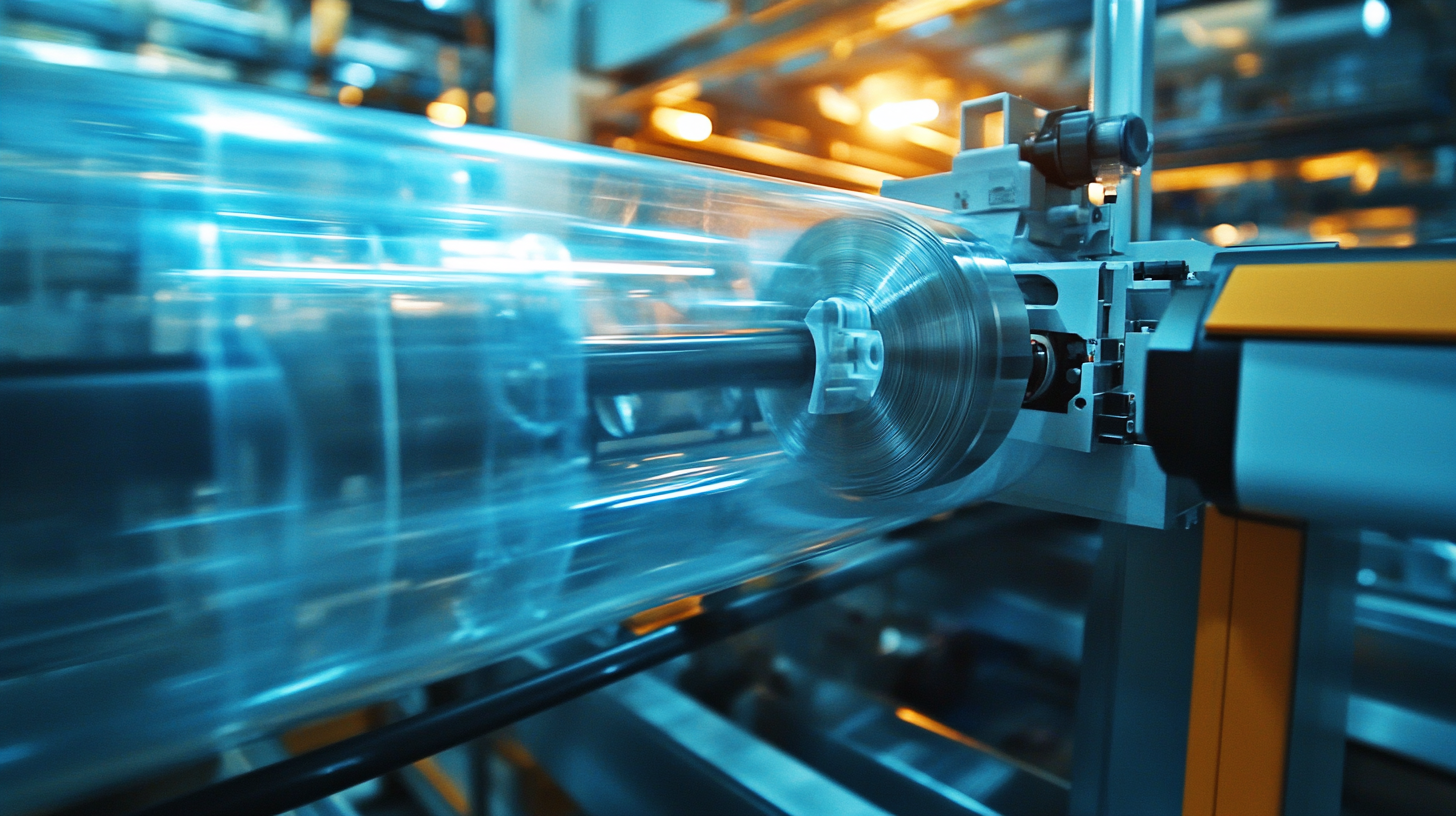

In the fast-evolving landscape of modern packaging,

efficiency and sustainability have become paramount for businesses striving to meet consumer demands while minimizing costs. The Film Blown Machine stands at the forefront of this transformation, revolutionizing the way packaging materials are produced and utilized. This powerful technology not only enhances productivity but also allows for the production of high-quality, durable films that cater to a variety of applications—from food packaging to industrial uses.

In this blog post, we will explore the numerous benefits of adopting the best Film Blown Machine for your operations and provide insights into how this vital equipment can streamline your processes, reduce waste, and ultimately unlock greater efficiency in your packaging solutions.

Whether you're a seasoned manufacturer or just starting out, understanding the advantages of advanced film blowing technology is key to staying competitive in today's market.

In the fast-evolving landscape of modern packaging,

efficiency and sustainability have become paramount for businesses striving to meet consumer demands while minimizing costs. The Film Blown Machine stands at the forefront of this transformation, revolutionizing the way packaging materials are produced and utilized. This powerful technology not only enhances productivity but also allows for the production of high-quality, durable films that cater to a variety of applications—from food packaging to industrial uses.

In this blog post, we will explore the numerous benefits of adopting the best Film Blown Machine for your operations and provide insights into how this vital equipment can streamline your processes, reduce waste, and ultimately unlock greater efficiency in your packaging solutions.

Whether you're a seasoned manufacturer or just starting out, understanding the advantages of advanced film blowing technology is key to staying competitive in today's market.

Identifying Key Qualities of Top Film Blown Machine Suppliers

When searching for top film blown machine suppliers, several key qualities stand out that can significantly enhance packaging efficiency. First and foremost, the level of technological innovation a supplier offers is critical. A leading supplier will leverage advanced features such as automation, real-time monitoring, and energy-efficient systems that not only streamline production but also reduce operational costs. Machines equipped with the latest technology often provide greater precision and consistency, essential for maintaining high-quality standards in packaging.

Another crucial aspect is the supplier's reputation and customer service. It's important to choose a supplier known for reliability and post-purchase support. A supplier willing to offer comprehensive training and maintenance services demonstrates their commitment to customer success. Additionally, positive client testimonials and industry recognition can serve as indicators of a supplier's capacity to deliver high-performance machines. Considering these factors when selecting a film blown machine supplier can lead to substantial improvements in packaging operations, ultimately unlocking greater efficiency for businesses.

Essential Features to Look for in Film Blown Machines

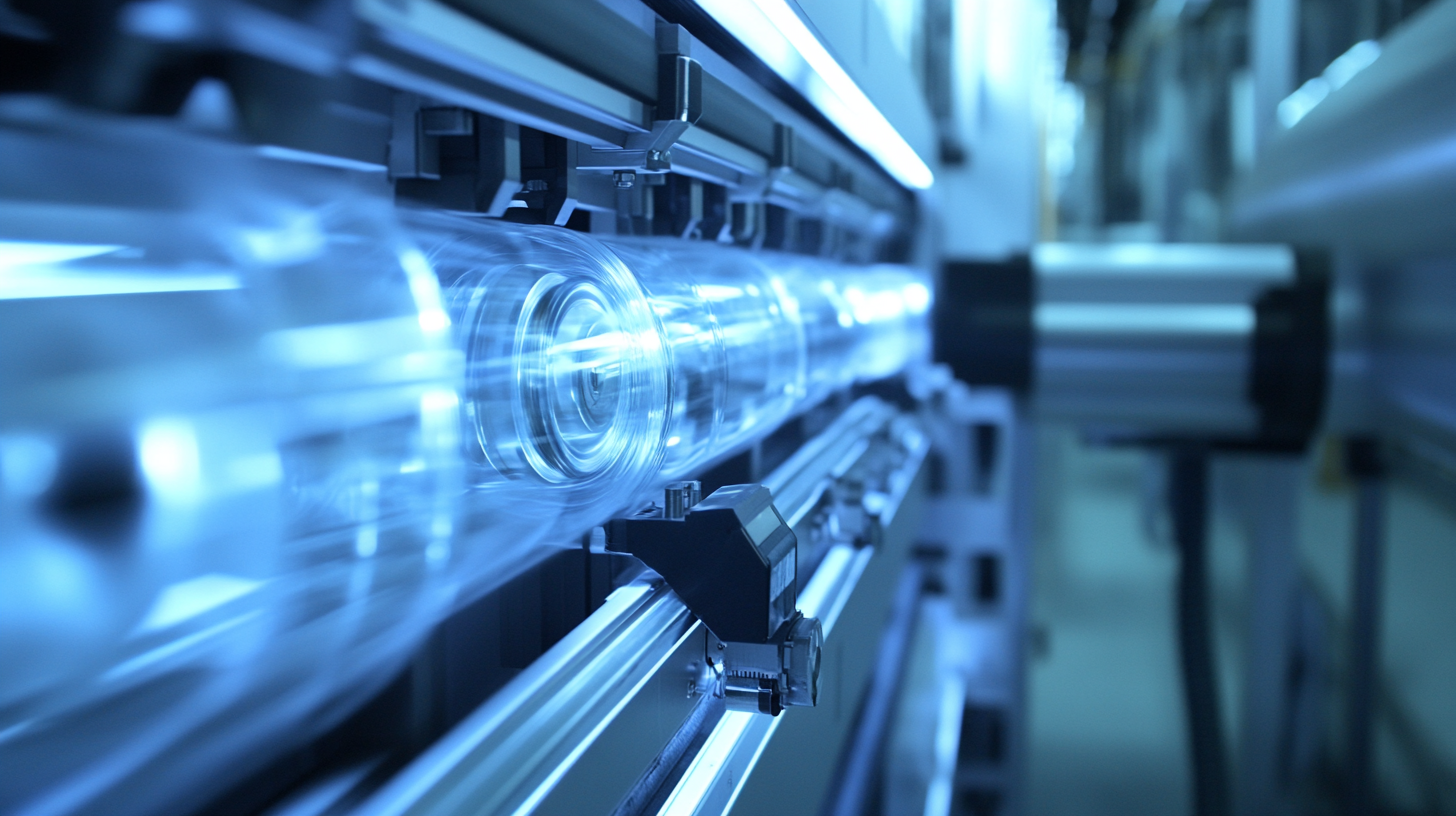

When selecting a film blown machine for modern packaging purposes, several essential features can dramatically enhance efficiency and productivity. First, look for machines equipped with advanced control systems that allow for precise adjustments of film thickness and width. This ensures that the packaging meets specific requirements while minimizing waste. Additionally, consider machines with multi-layer capabilities, as they can provide improved barrier properties and enhanced strength for the packaged materials.

Another key feature is the machine's speed and versatility. A high-speed film blown machine can significantly increase your output, making it ideal for businesses experiencing growth or increased demand. Furthermore, choose a model that can handle various types of resins. This flexibility allows for the production of different kinds of films, accommodating diverse packaging needs without requiring extensive machine changes.

Tip: Always research the machine's maintenance requirements. A user-friendly machine with easy access for servicing can prevent downtime and prolong the equipment's lifespan. Remember to read customer reviews and seek recommendations to ensure you're making a well-informed purchase. Investing in the right film blown machine can transform your packaging operations for the better.

Creating a Comprehensive Supplier Evaluation Checklist

When evaluating suppliers for the best film blown machines, it's crucial to establish a comprehensive supplier evaluation checklist. This checklist should assess key factors such as machine performance, ease of use, and manufacturer reputation. Additionally, consider the supplier’s after-sales support and warranty offerings. A thorough evaluation will ensure you select a supplier that can deliver not only a high-quality machine but also reliable service.

Tips for your checklist: First, prioritize performance specifications – how fast can the machine produce film, and what are its capabilities in terms of thickness and width? Second, research the supplier’s history and read reviews from other customers. A supplier with a solid track record can offer peace of mind. Lastly, assess the availability of spare parts and support services; a supplier that provides quick access to parts can significantly reduce downtime in your production line.

Incorporating these elements into your evaluation process will enhance your decision-making and foster a more efficient packaging operation. By taking the time to thoroughly assess potential suppliers, you'll be better positioned to unlock the transformative benefits that the best film blown machines can provide in modern packaging.

Unlocking Efficiency: The Transformative Benefits of the Best Film Blown Machine in Modern Packaging - Creating a Comprehensive Supplier Evaluation Checklist

| Criteria | Importance | Rating Scale (1-5) |

|---|---|---|

| Production Speed | High | 1 - 5 |

| Film Thickness Range | Medium | 1 - 5 |

| Energy Efficiency | High | 1 - 5 |

| Ease of Use | Medium | 1 - 5 |

| Maintenance Requirements | High | 1 - 5 |

| Material Versatility | High | 1 - 5 |

| Customer Support | Medium | 1 - 5 |

| Price Competitiveness | High | 1 - 5 |

Understanding Supplier Support and Service Options

When investing in a film blown machine for modern packaging, consideration of supplier support and service options is crucial for maximizing efficiency and productivity. A reliable supplier not only provides high-quality machinery but also ensures that ongoing support is readily available. This assistance can range from installation and setup to regular maintenance and troubleshooting. Having access to a responsive customer service team can drastically reduce downtime and enhance operational efficiency.

Moreover, it's essential to evaluate the training and resources that suppliers offer. Comprehensive training programs enable operators to understand the machine's features fully, leading to better utilization and fewer errors in production. Additionally, suppliers that offer proactive maintenance services can help identify potential issues before they become significant problems, safeguarding production schedules.

The right supplier partnership not only strengthens the performance of a film blown machine but also contributes to the overall success of packaging operations and customer satisfaction.

Evaluating Cost vs. Quality in Film Blown Machinery Investment

Investing in film blown machinery has become a crucial decision for packaging companies, weighing the cost against the anticipated quality and efficiency benefits. According to a 2022 report by Smithers Pira, the global flexible packaging market is expected to reach $302 billion by 2024, underscoring the growing need for advanced packaging solutions. High-quality film blown machines are at the forefront of this transformation, enabling businesses to produce superior packaging with enhanced durability and clarity.

When evaluating potential investments, companies must consider both upfront costs and long-term returns. A recent survey conducted by PCI Films Consulting revealed that manufacturers who invested in high-performing film blown machines reported an average efficiency increase of 30% and a reduction in material waste by up to 20%. These improvements can significantly offset initial expenditures, making quality machinery not just a choice, but a strategic advantage.

Furthermore, industry leaders are increasingly leveraging innovations like automation and real-time monitoring, which can enhance operational efficiency and quality control, driving better profit margins in the competitive packaging landscape.