Discover the High Quality of Film Blowing Machines from Leading Chinese Manufacturers

In the ever-evolving landscape of packaging technology, the Film Blowing Machine stands out as a pivotal piece of equipment for manufacturers aiming to produce high-quality plastic films. As industries continue to seek efficient and cost-effective solutions, leading Chinese manufacturers have emerged as key players, offering advanced machinery that blends innovation with reliability. This guide aims to delve into the features and benefits of these top-tier Film Blowing Machines, highlighting their role in enhancing production capabilities while ensuring superior film quality. By exploring the latest advancements in technology and the competitive advantages offered by Chinese manufacturers, this comprehensive guide will assist businesses in making informed decisions when investing in film blowing technology, ultimately supporting their growth in the packaging sector.

Emerging Trends in the Film Blowing Machines Market by 2025

The film blowing machines market is poised for significant growth by 2025, fueled by advancements in technology and increasing demand from various industries. According to a recent report by MarketsandMarkets, the global market for film blowing machines is expected to reach USD 3.5 billion, growing at a CAGR of 6.5% from 2020 to 2025. This growth is driven by the rising need for packaging solutions in the food and beverage, healthcare, and consumer goods sectors, where high-quality, flexible packaging is essential.

Emerging trends shaping the market include the integration of automation and smart technologies into film blowing machines. Automation enhances production efficiency and reduces human error, creating a more sustainable manufacturing environment. Furthermore, manufacturers are increasingly focusing on developing eco-friendly machines that use biodegradable materials, catering to the growing consumer demand for sustainable packaging solutions. A report from Grand View Research indicates that the biodegradable films segment alone is projected to grow at a staggering rate of 9.5% over the next five years, highlighting the shift towards more environmentally responsible practices in the industry.

Key Features to Look for in High-Quality Film Blowing Machines

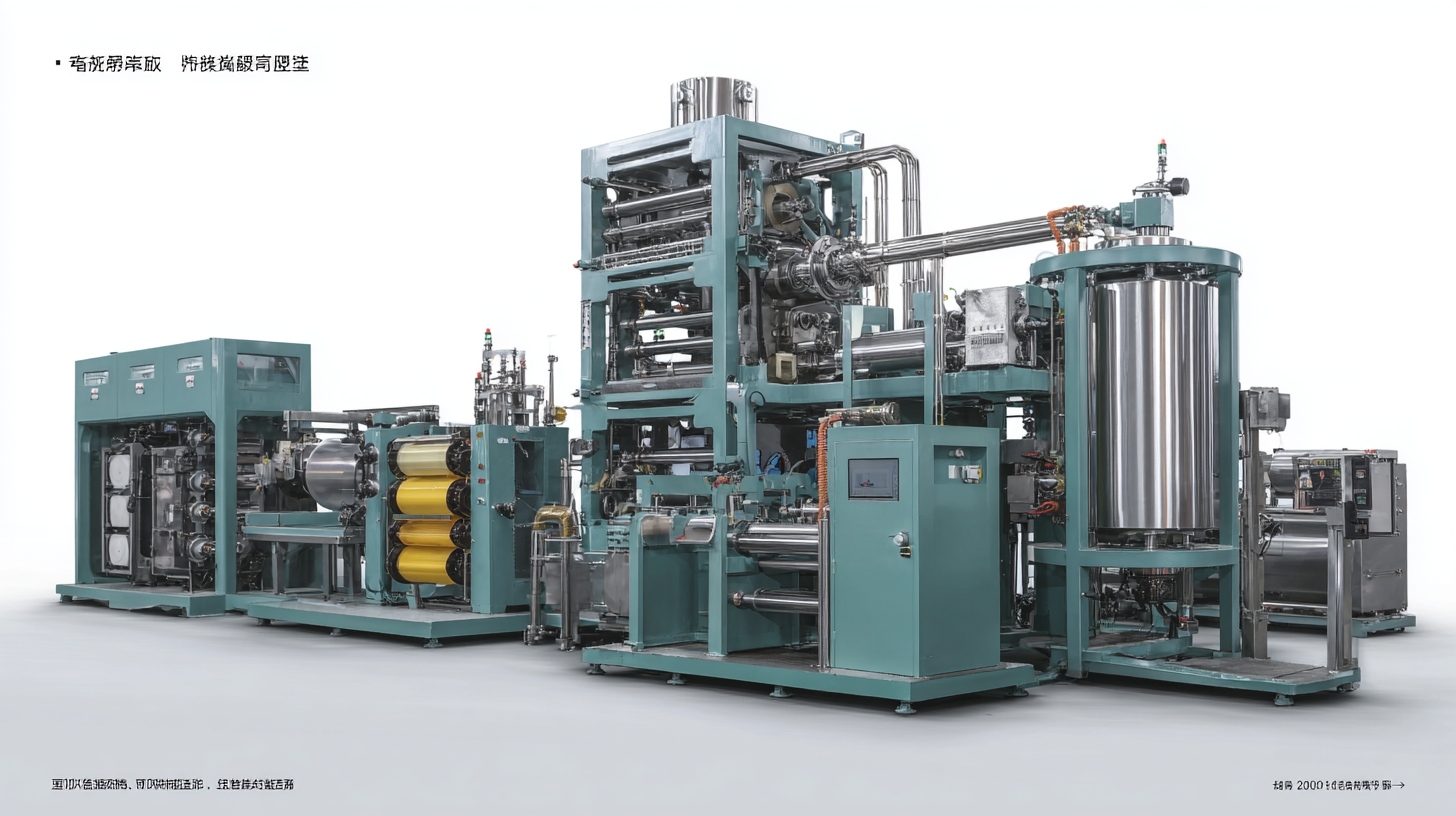

When exploring high-quality film blowing machines from prominent Chinese manufacturers, it's vital to focus on the key features that set these machines apart. First and foremost, consider the machine's production capacity. According to recent industry reports, advanced film blowing machines can produce films with widths of up to 2000mm and thicknesses ranging from 0.01mm to over 0.5mm, catering to diverse packaging needs. Additionally, look for features such as automatic thickness control systems that enhance consistency and reduce material waste, which is essential for maintaining competitiveness in the market.

Another critical aspect is the machine's energy efficiency. The latest models incorporate cutting-edge technology that can reduce energy consumption by up to 20% compared to older machines, as noted in a 2023 industrial study. This not only lowers operational costs but also aligns with sustainable practices that many industries are now adopting.

Tips: Always assess the durability of the equipment by checking the build materials and warranties offered by manufacturers. Furthermore, consider the user-friendliness of the machine's control systems, as intuitive interfaces can significantly reduce training time and boost productivity. Investing in a high-quality film blowing machine with these features will ensure a worthwhile addition to your production line.

Key Features of High-Quality Film Blowing Machines

Top Chinese Manufacturers Leading the Film Blowing Machines Industry

As the global demand for flexible packaging rises, the film blowing machines industry has seen significant advancements, particularly from prominent Chinese manufacturers. These companies are at the forefront of technology, innovating equipment that provides efficiency, reliability, and superior quality to meet the needs of various packaging applications. With their ability to produce both cast and blown film, these manufacturers are catering to diverse market segments, including stretch wrap and compostable packaging.

The stretch wrap market continues to expand, fueled by the need for protective packaging solutions in various industries. Chinese manufacturers have positioned themselves as leaders in this sector, offering machines that not only enhance production speed but also improve the quality of the films produced. Additionally, the compostable packaging equipment market is on track for substantial growth, driven by increasing environmental awareness and regulatory pressures. By embracing sustainability, these manufacturers are contributing to a greener future while meeting growing consumer demand for eco-friendly packaging solutions.

Comparative Analysis: Film Blowing Machines vs. Alternative Technologies

When evaluating film production technologies, it's essential to understand the comparative advantages of film blowing machines versus alternative methods. Film blowing machines, characterized by their ability to produce high-quality plastic films of varying thicknesses, excel in efficiency and consistency. The process involves melting plastic resin and forming it into a tubular film, which is then cooled and wound into rolls. This methodology not only enhances production speed but also ensures uniform properties in the final product, making it a favored choice in packaging industries.

In contrast, alternatives such as cast film extrusion and stretch film technologies have their place but often fall short in versatility. Cast film extrusion, while effective for certain applications, can lead to higher production costs and lower output speed compared to film blowing. On the other hand, stretch film technologies are primarily suited for specific applications like pallet wrapping and often don’t offer the same breadth of film thickness or quality. This comparative analysis clearly highlights the superiority of film blowing machines from leading Chinese manufacturers, marking them as the preferred option for businesses aiming to maintain high production standards and cost-efficiency.

Future Prospects: Innovations Shaping the Film Blowing Machines Landscape

The landscape of film blowing machines is rapidly evolving, driven by innovative technologies and the increasing demands for high-quality plastic films. As leading Chinese manufacturers invest heavily in research and development, they are pioneering advancements such as automatic control systems and enhanced materials that not only improve productivity but also ensure consistent quality. These innovations enable manufacturers to produce thinner and stronger films, which are essential for various applications in packaging and agriculture.

Moreover, sustainability has become a key focus area for the future of film blowing machines. With the global push towards eco-friendly solutions, manufacturers are exploring biodegradable materials and energy-efficient production processes. The integration of smart technology, like Internet of Things (IoT) capabilities, is also on the horizon, allowing for greater monitoring and optimization throughout the production cycle. These developments promise to reshape the industry, ensuring that Chinese manufacturers remain at the forefront while meeting the increasingly stringent environmental standards and consumer expectations.